Home > Services > Product engineering > High-grade surface plastic solutions

High-grade surface plastic solutions

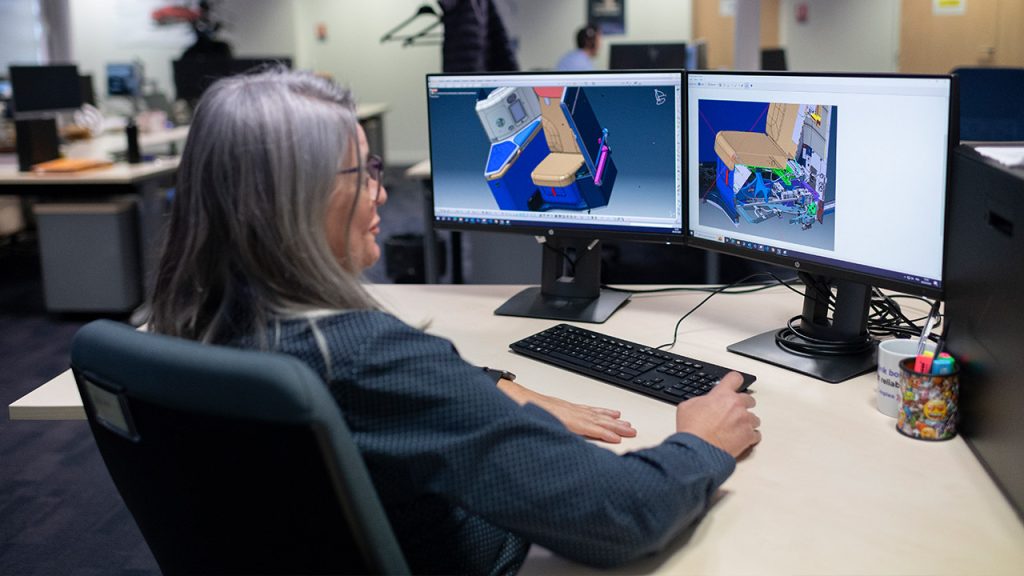

We deliver production-ready design for high-quality plastic and composite components that end users see, touch, or engage with, to aerospace, automotive, rail, medical devices and other manufacturing industries.

Our cross-functional team (styling, A class modelling, product design and Mould design) and our zero-lag approach enable us to optimise the cost and the time to market, without aesthetic compromise.

We have over 30 years of experience in delivering plastic part design and Mould design, and an ecosystem of 300+ FTEs across the world.

Custom solutions for your needs

Studio Engineering

Support industrial designers to keep their design intent, by anticipating the feasibility issues in

- Cutting

- New finishes

Function Development

Develop the full function for the product team, with the integration of electronic features such as

- Prototype design

- Serial process design

- Functional testing

- Serial product tuning

Expertise Support

Technical support for different project phases such as

- Digital surface modelling (A Class surface)

- Product engineering

- Process engineering

- Design for cost

And provide consulting services for supplier management.

Training

Master injection moulding and composite materials, from initiation to advanced level.

Common challenges in Plastic Solutions

Increasing pressure to release more products in a shorter time span. Future vehicle development will be shortened by 25%, from 54 to 40 months.

Greater emphasis on lightweight and sustainability. On average, plastics make up less than 10% of a vehicle’s weight, yet account for approximately 50% of its volume. It is estimated that reducing vehicle weight by 10% can result in a 6 to 8% improvement in energy efficiency.

Customers demand higher quality and sustainable materials. 33% of clients said they would be willing to pay more for higher surface quality in a vehicle, and 57% of users value sustainable materials

These trends demand improvement in engineering to reduce the number of appearance and geometric defects in the early stage of the project to ensure optimal time to market and cost.

Expleo’s approach to rapidly deliver production-ready design

A cross-functional centre of expertise of designers, engineers, and mold designers to limit the validation loops (time and cost) by anticipating implicit requirements and technical issues.

An independent expert team that can challenge the design of the client or the rules of the supplier, to master the cost and the final design of your product.

The support of a global engineering services provider that will enable the clients to leverage our resources of 19,000 consultants for their extended needs in systems development or industrialisation.

Top rated partner

of French leading automotive manufacturers

N°1 partner

of the world leader in snowmobile

Over 30 years of experience

in plastic part and mould design

FAQ

We develop products such as dashboards, interior/exterior trims, bumpers, door panels, tailgate, spoilers, air vents, seat trims, radomes, electronics packaging and home appliances.

We utilise various software programs depending on the service provided. Below are some examples:

- Creative design : Photoshop, Blender, VRED, Alias

- A-class modelling : Alias, ICEM Surf

- Engineering : CATIA, Creo, SolidWorks

- Process engineering : Moldflow

- Computer-Aided Engineering (CAE) : Abaqus, Radioss, Pam-Crash, LS-DYNA

From consulting, competence centre, service centre, work unit, work package to small batch of components/prototypes.

We have already delivered our solutions and prototypes to clients in over 30 countries, including France, Germany, the UK, Spain, Italy, Croatia, Romania, Canada, China, Morocco, and India.

Contact our sales team

After completing the form one of our experts will get in contact with you as soon as possible.

If you are looking for job opportunities, please click here.