3 ways to help your engineering team become super-efficient

18% of Expleo’s UK & Ireland client projects in product engineering (mechanics, embedded systems, etc.) aim to optimise our clients’ process efficiency.

Our clients include leading organisations such as Airbus, Bosch, BMW, Jaguar Land Rover, Stellantis and Thales.

As a leading engineering services provider in Europe, we have worked with hundreds of leading manufacturers in the aerospace, defence, automotive, railway, energy, and healthcare industries, and have noticed that heads of engineering often face frustration with:

Increasing complex products

As most products today include electrical, mechanical and software components, with new materials, smaller package sizes and tighter tolerances.

Shorter deadlines and budget squeezed by inflation

As an example, Volkswagen aims to cut the time to develop new models by almost 40% to keep pace with faster-moving rivals (Reuters).

Talent shortage

It is estimated there is a shortfall of over 173,000 workers in the UK STEM sector (IET).

Unfortunately, these challenges not only affect your team but also hinder your organisation’s ability from being resilient to new and unforeseen challenges, such as changing regulations or offset agreements.

Through analysis of over 1,000 client engagements spanning various industries, we identified the most common operational roadblocks faced by organisations today.

Product engineering managers – in a bid to overcome barriers specific to your function and enable you to save time, energy, and resources, begin by asking these three questions at the start of the project.

1. How can I become a data-driven leader in an engineering project?

Intuition and personal experience are no longer enough to succeed in modern complex product engineering projects. With hundreds or thousands of engineers and dozens of departments involved, data becomes essential to support your decision-making (e.g., avoid project delays, workload balancing, cost estimation, etc.).

Several parameters should be tracked to prevent an engineering project from veering off course. According to our expert in engineering programmes and project quality, it is essential to monitor the team commitment, continuous progress, milestone schedule consent and common target.

However, we understand that setting up an effective data reporting system is not always easy and IT departments may be uncooperative.

Barring understanding of databases and data management, the human aspect poses the greatest hurdle to developing a reliable and effective decision-making tool. Our data consultants who have R&D engineering experience have supported several heads of engineering to set up and unify their data reporting systems.

My experience of being super-efficient in any Data analytics projects: before rushing headlong into technical solutions, get all your stakeholders around the table to establish a consensus on a single source of truth: What KPIs? How do we calculate them? What are the data sources? What will be the level of trust?

2. What if my team can design it right the first time?

If you strive for first-time quality (an approach more prevalent in production than in engineering), you can benefit from many advantages:

- Save time and costs caused by corrections or reworks

- Avoid delays caused by miscomprehensions regarding requirements

- Gain your organisation’s trust by providing flawless deliverables.

Pierre Fraisse, our Global Go-To-Market Leader in Product and Process Quality, observes numerous instances in engineering programmes, where projects go off-track with design defects or delays, when the kick-offs are not well prepared. It may seem simple, but ensure that all stakeholders are aware of:

- The end goal of the product

- The project deadline and milestones

- The inputs/outputs of each team.

When communication is not effective, teams may waste time doing low-priority projects or developing a system misaligned with the requirements, causing the project to fail at meeting its deadline.

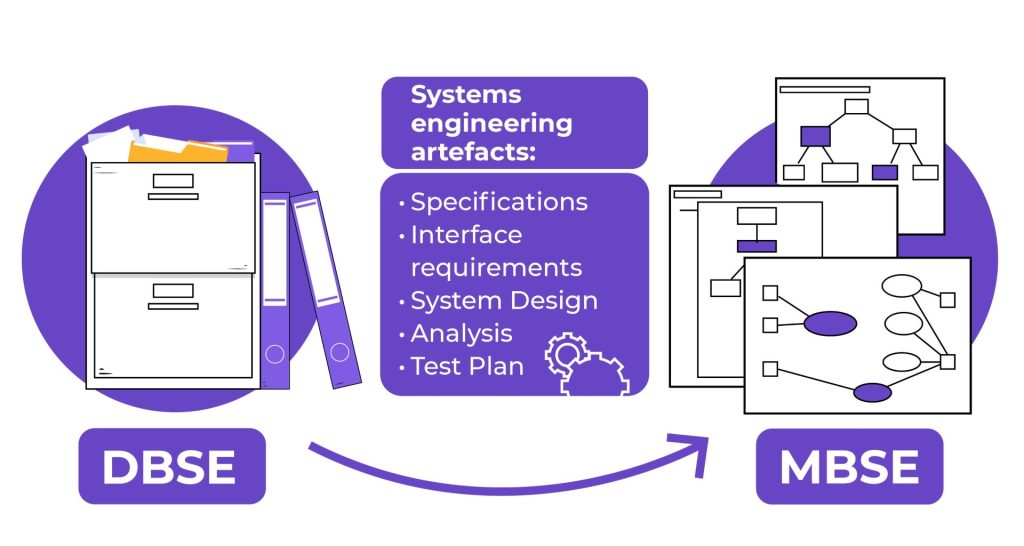

To communicate effectively, a modern approach in engineering is Model-Based Systems Engineering (MBSE). It translates requirements into a universally understandable project vision, reducing design error risk and improving efficiency throughout the development life cycle, from design to testing.

In short, by replacing the document-centric approach that has been practised in the past and using domain models as the primary means of information exchange, MBSE can make your engineering teams become super-efficient.

When everyone is aware of the big picture, fewer errors are made, which leads to increased productivity. Since the developer understands more quickly, they do not have to do rework, and they are more efficient than if they based their development solely on textual requirements. Therefore, the entire project gains efficiency.

3. What if my engineers could focus 100% on high-impact activities?

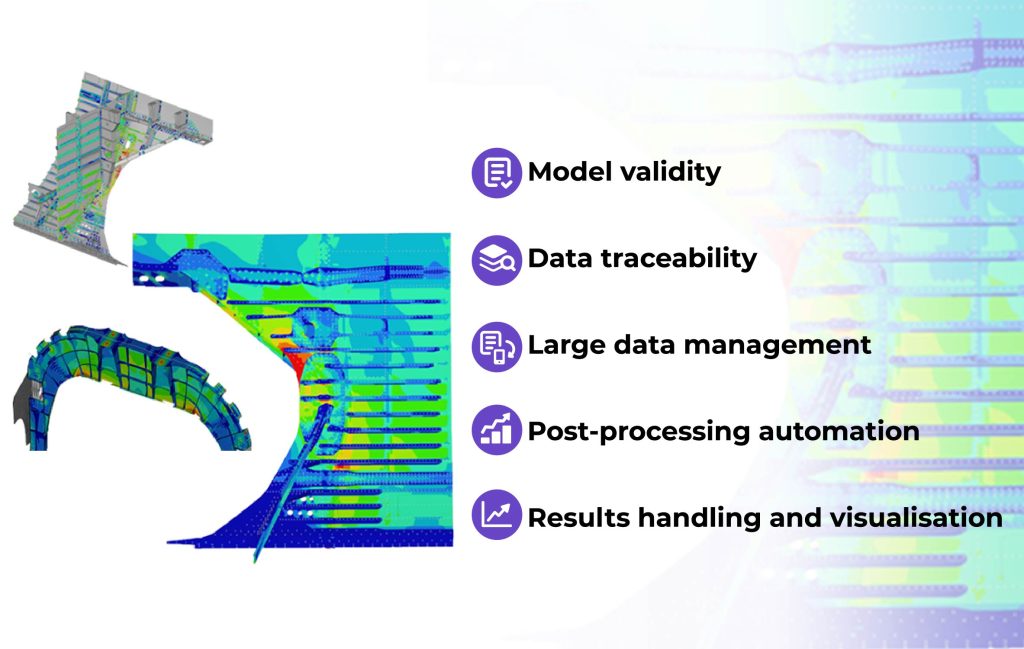

In order to allow your engineers to focus on their core strengths, you need to pinpoint any repetitive tasks that are slowing them down and determine if they could be automated.

Another domain we can automate is embedded software development. The amount of embedded code needed to run modern products is exploding: while a 1980s NASA Space Shuttle required roughly 400,000 lines of code, a 2018s Ford 10-speed automatic transmission has just over a million lines of code (Eureka!).

That is why our engineering teams introduce the method of Model-based design in our client’s activities. It is a modern embedded software development process in which the primary focus and products are software models (with Mathlab Simulink) rather than directly code in C/C++. Then the software models (based on the requirements) can generate the embedded code automatically.

The MBD methodology and tools are a highly effective lever for all aspects of embedded systems development. They simplify software development, make the code easier to maintain, ensure scalability of the tool, provide long-term vision with gains for every future project, and streamline processes. Efficiency benefits are numerous and significant, especially when it is challenging to recruit C/C++ experts.

WHO IS EXPLEO?

Expleo is a global engineering, technology and consulting service provider powered by 17,000 highly-skilled experts.

We benefit from more than 40 years of experience developing complex products, optimising manufacturing processes, and ensuring the quality of information systems for leading organisations, such as Airbus, Jaguar Land Rover, NHS and Ofgem.